CLADDING STEEL PLANTERS WITH OTHER MATERIALS OPENS UP LIMITLESS SCOPE FOR PLANTING DESIGN.

All our steel manufacture is to-order and to your specification, and we do not hold in stock a standard range of shapes and sizes.

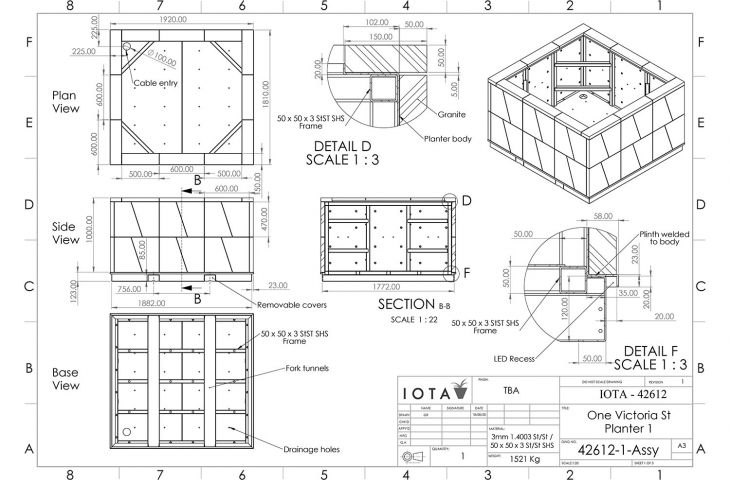

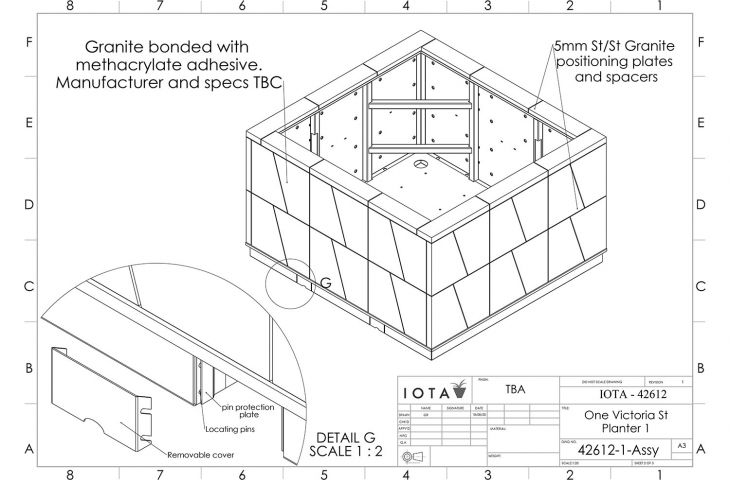

IOTA has developed and refined techniques to apply a wide range of cladding products directly to steel planters. The clad planters deliver the desired aesthetic of the exterior cladding, whilst relying on the superior strength and strength-to-weight ratio of steel for the planters’ technical performance. As a result, the clad steel planters are typically stronger, lighter and cheaper than alternative methods of construction; and the design flexibility of the steel manufacturing process extends the use of cladding into environments and applications which were previously not possible.

Myriad cladding products are available on the market – including:

- ceramic and porcelain tiles

- slate, granite and other stone tiles

- timber and wood panelling

- high-tech composite materials, such as Aluminium Plastic Composite

- precast architectural cladding products

Within a planting design, the creative scope of clad steel planters is limitless; and the planters can serve many uses – for example:

- to match, or complement, existing hard landscaping materials

- to meet planning conditions, in terms of the style and character of existing fascias

- to create highly individualised schemes, based on the decorative possibilities of cladding

Using allied techniques, IOTA can also combine steel planter structures with soft metals [such as brass, copper and lead], yielding similar benefits – as further described in the section Lead Planters.