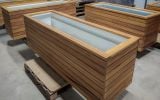

CLADDING TIMBER ONTO STEEL CREATES TIMBER PLANTERS ABLE TO MEET THE MOST STRINGENT DESIGN AND TECHNICAL PERFORMANCE REQUIREMENTS

All our timber and steel manufacture is to-order and to your specification, and we do not hold in stock a standard range of shapes and sizes.

Naturally beautiful, thermally insulating, and minimal-maintenance – timber can be a good choice for planters.

There are many ways to create planters from timber, to suit a wide range of aesthetic, budgetary and technical performance objectives. And, in the majority of cases, a simple all-timber construction using inexpensive treated softwoods is both a cost-effective and perfectly adequate solution.

However, IOTA tends to be asked to supply relatively high-end projects, where:

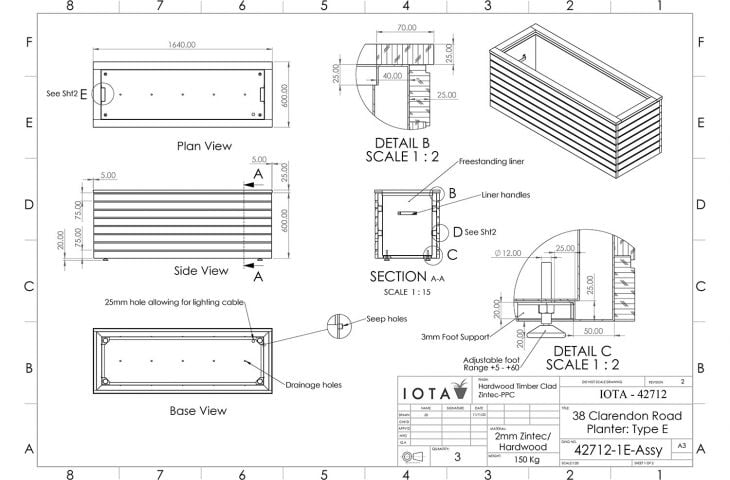

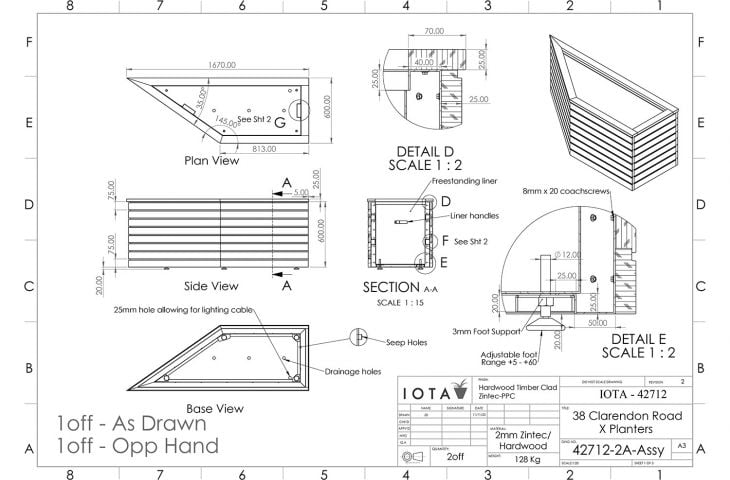

- expensive hardwoods are typically specified

- a very high level of finish and timber stability, over a very long period of time, is demanded

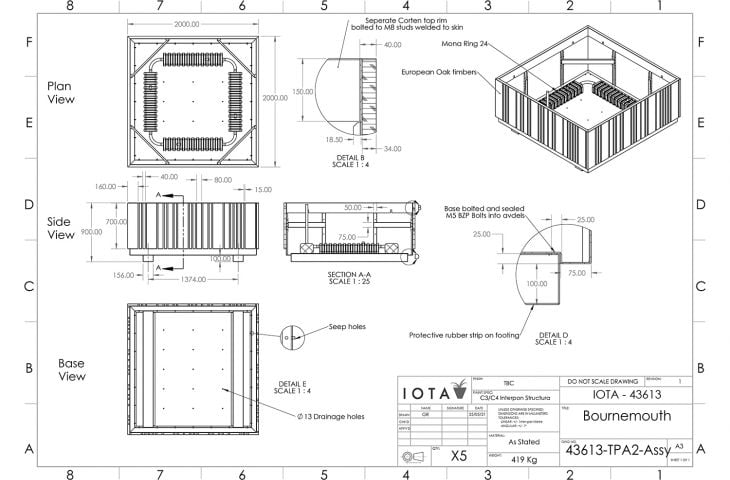

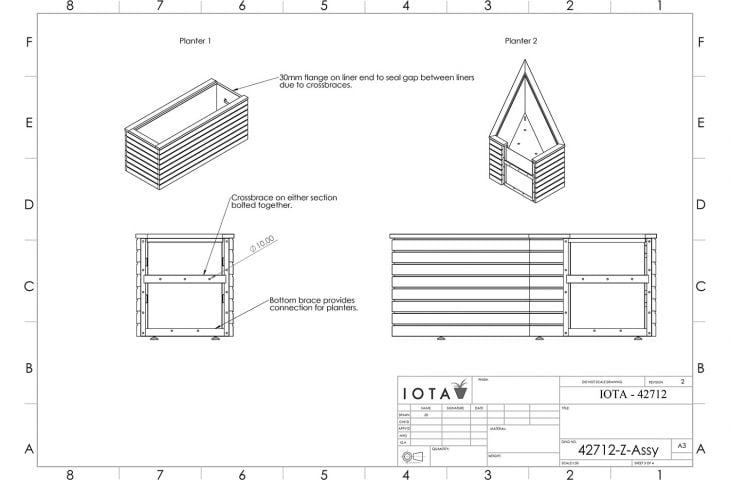

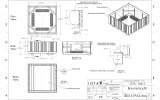

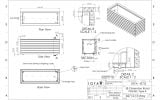

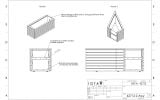

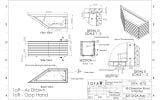

- the planters tend to be large in scale, with production and logistical constraints dictating that the planters will need to be split into more manageable units, for on-site assembly

- there are typically complex design integration requirements [such as substrate support fastenings, edge protections, irrigation systems, drainage systems, adjustable feet, lighting etc.]

- contractual terms are commensurate with the project value, and extended warranties etc. apply

For those kinds of projects, in which IOTA specialises, there are strong arguments in favour of using timber as a cladding, securely fastened to a structural planter in a material which is strong, stable, waterproof, and which can be manufactured to fine design tolerances – such as steel.

In this design solution, it is not fair to say that the timber is ‘purely decorative’, as the timber will greatly contribute to the overall rigidity of the structure, and to thermal insulation. However, it is true that much thinner timbers can be used – and, with hardwoods, that can save a lot of money.

And it is the inner steel planter that is ‘taking the strain’, and maintaining the structure and finish; and steel is a much more precise, strong and flexible material for the kinds of design integration described above, and for on-site assembly. And, finally, it is ultimately the superior technical performance of the steel that is underpinning the contractual warranties etc.