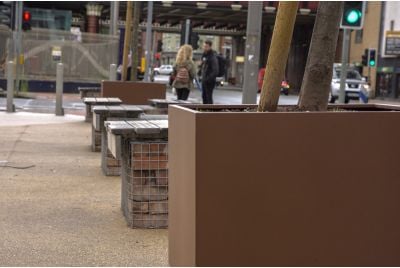

Powder coated steel planters offer limitless scope for colour customisation, combined with a durable, hard-wearing and flawless surface finish.

Information on this page concerns our fully bespoke manufacturing service. For simple square and rectangular shapes our standard range of powder coated planters may be suitable.

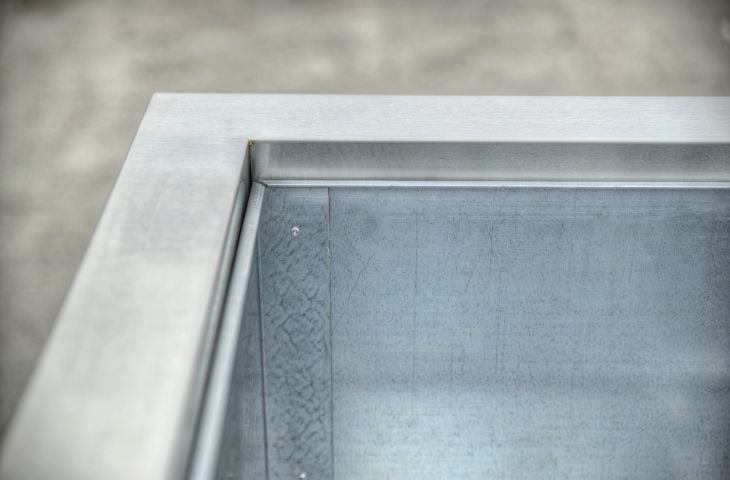

The steel planters are fabricated, then ground and polished to produce perfectly smooth and seamless corners and edges; before being sprayed with a fine powder containing pigment, hardeners and bonding agents. They are then oven baked to 200°C to cure the paint finish. Standard colours can be selected from the RAL Classic series (over 200 shades), in a semi-matte finish. In addition, there are a wide range of specialist powder coat colours and finishes available.

The planters can be manufactured using a range of different steels, to suit the particular budget and quality requirements of the brief. For example:

- We commonly use 2mm thick steel sheet, but depending on planter size and demands of the site 1.5mm or 3mm may be preferable.

- We consider Zintec steel (zinc plated for enhanced longevity) to be the best value option for most situations. However, applying zinc primer to mild steel instead can deliver a more than fit-for-purpose planter where budgets are tight.

- For commercial/public realm environments, or for siting near the coast, powder coated planters can be manufactured using stainless steel, rather than Zintec steel.

- Where weight is an issue, aluminium can be used instead of steel, and then powder coated via the same process.

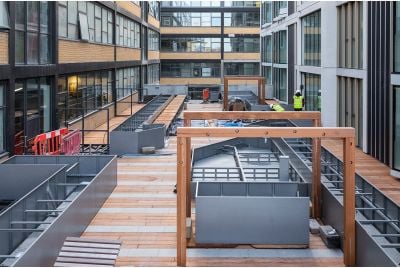

IOTA custom-manufactures powder coated steel planters in any shape or size, from simple geometric shapes to complex architectural designs. CAD models can also be generated for approval of any powder coated steel planters against a design brief.

![Planters powder coated to RAL 3013 [Tomato Red]](https://www.iotagarden.com/image/cache/data/bespoke_products/powder%201.1-1-730x480w.jpg)

![Planters powder coated to RAL 3013 [Tomato Red]](https://www.iotagarden.com/image/cache/data/bespoke_products/powder_10-730x480w.jpg)

![RAL 2003 [Pastel orange] for Manchester University](https://www.iotagarden.com/image/cache/data/bespoke_products/thumb%20ppc-730x480w.jpg)

![RAL 2003 [Pastel orange] for Manchester University](https://www.iotagarden.com/image/cache/data/bespoke_products/Man%20Uni%201-730x480w.jpg)

![RAL 2003 [Pastel orange] for Manchester University](https://www.iotagarden.com/image/cache/data/bespoke_products/Man%20Uni%205-730x480w.jpg)

![Planters powder coated to RAL 3013 [Tomato Red]](https://www.iotagarden.com/image/cache/data/bespoke_products/powder%201.1-1-160x100w.jpg)

![Planters powder coated to RAL 3013 [Tomato Red]](https://www.iotagarden.com/image/cache/data/bespoke_products/powder_10-160x100w.jpg)

![RAL 2003 [Pastel orange] for Manchester University](https://www.iotagarden.com/image/cache/data/bespoke_products/thumb%20ppc-160x100w.jpg)

![RAL 2003 [Pastel orange] for Manchester University](https://www.iotagarden.com/image/cache/data/bespoke_products/Man%20Uni%201-160x100w.jpg)

![RAL 2003 [Pastel orange] for Manchester University](https://www.iotagarden.com/image/cache/data/bespoke_products/Man%20Uni%205-160x100w.jpg)

-400x268w.jpg)

-400x268w.jpg)

-400x268w.jpg)

-400x268w.jpg)