We can make a tree planter to any size, shape or design / arrangement. However, above a certain size, production economics and logistical constraints dictate that the planter must be sectioned – as fully described here: DESIGNING LARGE SCALE PLANTERS IN MULTIPLE SECTIONS >>

In this article, we will limit discussion to simple, geometric, square, fully-fabricated [i.e. not sectioned] tree planters – up to the maximum size that can be made and transported cost-effectively. This limits the maximum Length x Width profile to 2400mm [which is the maximum width of an artic trailer], and the maximum Height to 1000mm [which is the maximum Height that can be fabricated from a single sheet of standard [i.e. cheap] stock sheet metal, where the other dimension is 2400mm].

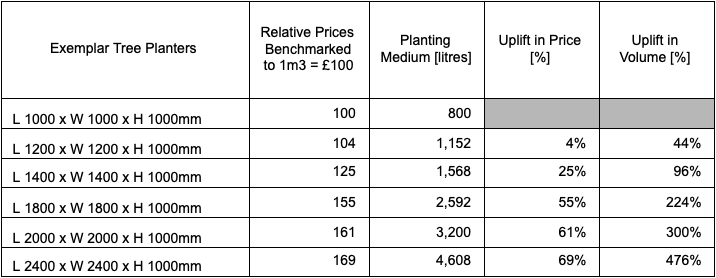

To assist with discussion of value-for-money, weights and loadings etc., we will use a set of exemplar tree planters with dims. as below:

L 1000 x W 1000 x H 1000mm [1m3 is really the smallest size for a ‘tree planter’]

L 1200 x W 1200 x H 1000mm

L 1400 x W 1400 x H 1000mm

L 1800 x W 1800 x H 1000mm

L 2000 x W 2000 x H 1000mm

L 2400 x W 2400 x H 1000mm [the maximum size, as defined above]

They do say that ‘size matters’. However trees don’t care about length, but about volume – specifically the volume of planting medium they can consume, before they really need to be transplanted [either into a larger planter, or into open ground].

The good news is that:

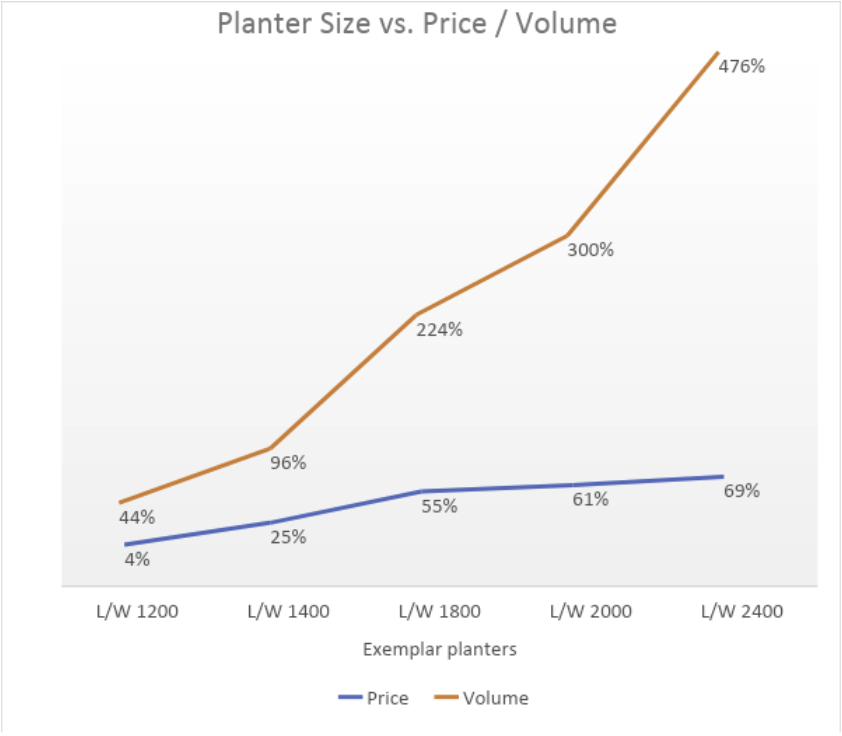

To illustrate this point, let’s use our exemplar tree planters, as above; and let’s assume that 200mm of the planters’ heights are ‘lost’ to a drainage layer at the bottom, and a mulch layer at the top [the planting medium being between these two layers]. The smallest, 1m3 planter is benchmarked at a notional £100, and other prices are shown as a % uplift from that benchmark. These are the figures:

From this analysis we can see, for example, that:

So ‘bigger is definitely better’ – in general terms, and all other things being equal.

This is one of the most common FAQ with tree planters – and the good news is that loadings are almost never an insurmountable problem.

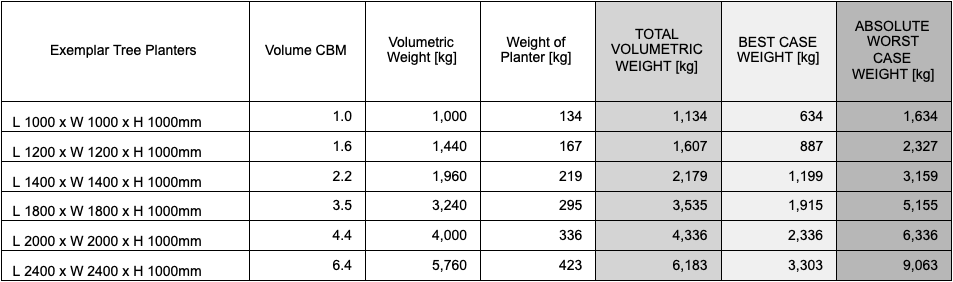

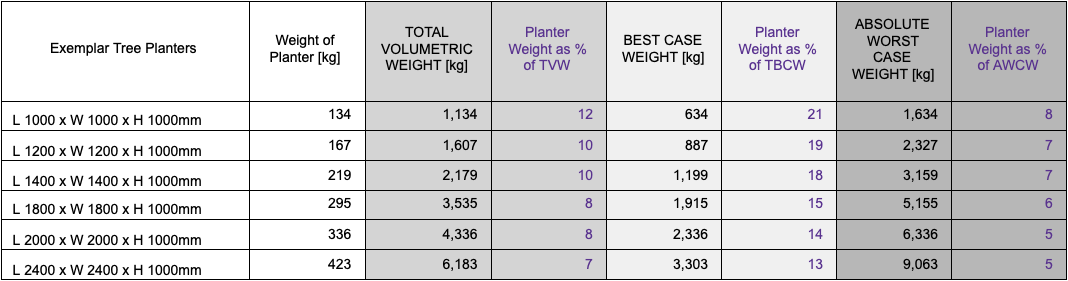

We are often asked to estimate the weight of the planters, but that information is, in fact, of very limited value. In the vast majority of conventional planting schemes, the planter itself is normally less than 10-20% of the total planted weight; and 80-90% of the weight is down to the planting [drainage materials, soil/compost, water, plants/trees etc.]. So, if weight is genuinely an issue, then the way to address it is via the design of the planting, not the specification of the planter.

In terms of trying to estimate total planted weights, nothing to do with plants/planting is a perfect science [not least, as assumptions are wholly dependent on conditions - particularly as it relates to water saturation]. However, it is generally accepted that a metal planter [unless it has a very big/heavy tree in it] will weigh less than the volumetric weight based on 1 CBM = 1 tonne.

This volumetric weight would be an operational worst case, in most circumstances; and it is more likely that a basic shrub planting scheme would be only 50% of that weight. However large trees can, over time, add quite a lot to the weight, so it is prudent to apply a 50% uplift in those unusual circumstances – as an absolute worst case.

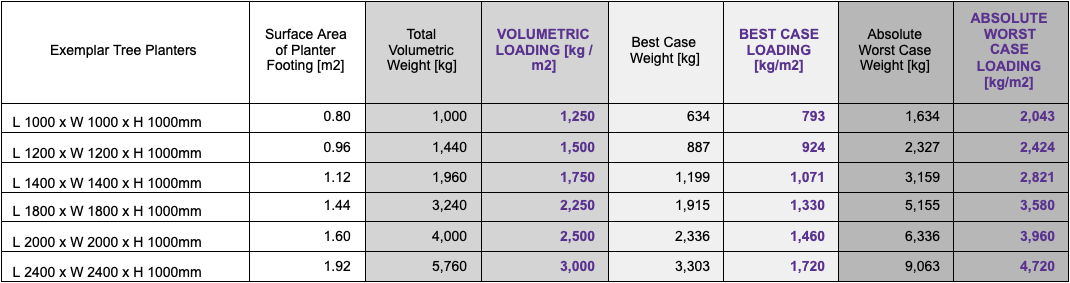

These are the estimated weights for our exemplar tree planters:

Notes:

* Volumetric Weight is based on 1 CBM = 1 tonne [1000kg]

* Total Volumetric Weight is based on Volumetric Weight + Weight of Planter

* Best Case Weight is based on 50% of Volumetric Weight + Weight of Planter

* Absolute Worst Case Weight is based on 150% of Volumetric Weight + Weight of Planter

And as stated already, and as you can see from the figures below, weight is really all about the planting, rather than the planters.

One final comment on weight… If your figures come out a lot higher than using the above logic, then the most likely cause is that the wrong figures for the planting medium are being used. Top soil is VERY dense, and will generate very high figures; but top soil must NEVER be used in planted containers. A lighter-weight, more free-draining planting medium must always be used – as fully discussed here: GROWING MEDIUMS AND RESERVOIRS FOR PLANTERS >>

Turning now to loadings, this is generally taken to be the weight applying to a certain surface area.

There are, of course, a wide range of situations in which tree planters may be deployed; and loadings will be a non-issue in some [such as when tree planters are placed onto street paving in public realm], and a serious consideration in others [such as when tree planters are placed onto an insulation layer on a roof terrace]. In the latter situations, the concerns are almost always contractual [such as relating to warranties] – so the numbers must be run, to gain the required approvals.

The simplest solutions to mitigate loadings are to either: [i] design a wide footing to the planter of [say] W 200mm [instead of feet, as standard]; or [ii] place the planter onto low/wide pedestals, such as Wallbarn Mini-Pedestals >>. The first solution will work for planter installation above FFL, but it does not allow for levelling; whilst the second solution allows for levelling, but it will only work below FFL [such as when the planter is placed on the insulation layer, and is then surrounded by paving slabs on their own pedestals]. In either case, however, the planter’s weight will be spread across a W 200mm area around the entire planter perimeter.

The following loadings would result:

These seem like some pretty scary figures, but in fact they are not. To put it into context, imagine a regular 15 stone man standing on the ball of his foot – that doesn’t sound too scary…? However 15 stone is 95kg, and the ball of his foot is going to be no more than 10cm2. That actually multiplies out at 9,500kg [or 9.5 tonnes] per m2 – and that is truly a scary number…! But does his foot fall through the roof, or does the roof terrace collapse…? Hardly. And under a normal worst case scenario [Volumetric Loadings], the planter loadings are a fraction of the point loadings that arise from the 15 stone man standing on the ball of his foot.

So, in the vast majority of situations, point loadings will not be an issue – but, of course, total loadings might well be an issue, if the planting scheme is particularly ambitious and expansive. In other words, it might be OK to have twenty 15 stone men standing on their tippytoes on the roof terrace, but it might not be OK to have a hundred of them. In the final analysis, these decisions will normally be for others to take [such as a Structural Engineer], but the above figures can at least provide an initial basis for evaluation and discussion of loadings.

Relative to a landscaping scheme based around simple shrub planters, a tree planting scheme tends to be a lot more ambitious and expensive, and thus expectations of return-on-capital and longevity tend to be higher. Also the growth of trees, over the years, can place the planter under much greater strain than with shrubs, so tree planters typically need to be specified at a sufficient level to be ‘future proofed’.

Aluminium has distinct merit in some situations – as discussed here: STEEL VS. ALUMINIUM – WHICH METAL SHOULD I SPECIFY? >> However, Aluminium is a poor choice for tree planters. Aluminium is a lot more expensive than Steel; and in sheet form it is a lot less stiff than Steel, so typically one has to ‘gauge up’ with Aluminium [i.e. to achieve the same strength and stiffness as 3.0mm Steel, one might need to use 4.0mm or 5.0mm Aluminium]. So with the kinds of loadings that can be expected with a tree planter, Aluminium works out extremely expensive, and it is almost never specified for this design application.

So it is really down to what choice of Steel. Unless at the ‘entry point’ of a 1m3 tree planter [where 2.0mm thickness might do], any other size of tree planter must be at least 3.0mm Steel. In extreme situations only, 4.0mm might be cost-justified – but generally 3.0mm is sufficient up to the largest size discussed here – L 2400 x W 2400 x H 1100mm.

As to what choice of Steel, the lowest-cost fit-for-purpose option will always be some form of Galvanised Mild Steel [such as Zintec] with a high-quality Polyester Powder Coat [PPC] paint finish. However, as said, expectations of return on capital and longevity tend to be high with tree planters, and they are often to be located in high-traffic public – so there is a strong argument to consider 1.4003 Stainless Steel for tree planters. This option is fully discussed here: 1.4003-GRADE STAINLESS STEEL - THE UNIQUE ADVANTAGES >> Alternatively, Corten Steel has a great deal to commend it for tree planters, so long as the aesthetic works with the brief - see here: CORTEN STEEL - THE FACTS AND THE UNIQUE BENEFITS >>

Relative to simple shrub planters, tree planters will need to be robustly strengthened. For simple, geometric, square tree planters, as discussed here, the simplest solution is to have internal cross braces, in a diamond configuration to allow space for the tree root ball. Larger tree planters might also need to have bracing across the corners; and further strengthening will be required if the planter is to be moved – as below.

In public realm, it is common for tree planters to be placed over underground utilities, in which case the spec. might call for them to be movable – even if only in an emergency.

The cheapest solution is to make a tree planter movable via forklift or pallet truck – several design options exist, as fully discussed here: MOVING PLANTERS WITH PALLET TRUCKS OR FORK LIFTS >> Relative to static tree planters, there is a modest additional cost for strengthening to be movable by forklift or pallet truck.

However, each of the above options introduce a void space under the planters; and, on larger schemes, with large tree planters, Environmental Health may object, on the basis that these voids could create rubbish traps and/or vermin habitats. In such cases, the only option is to make the planters liftable from above, via sturdy eye bolts welded inside the rims. The rims, and the entire planter bodies, also have to be strengthened against crushing loadings [typically by creating a complete internal box section frame within the planters]; and often a lifting rig must be designed, fabricated and certified, specific to the planter and tree. All of this makes lifting from above a lot more expensive than lifting from below via forklift or pallet truck. A good project to review for lifting from above is: SNOWHILL THREE, BIRMINGHAM B4 >>

The only silver lining is that, where lifting from above is mandated, it is often in situations where the tree planters are particularly massive, and the trees will likely be massive too, and in need of aerial guying. So the eye bolts welded inside the rims can serve a dual function – as further described below.

Any tree above a 10/12cm girth will need to be ‘staked’; and conventional tree stakes, used in open ground, really don’t work in planters. The alternative solution is to fasten the root ball with a tree anchoring system. Many of these systems are available on the market, and they all work in essentially the same way – by cradling the root ball, and anchoring it down to 3 or 4 secure points underneath. With sheet metal tree planters, it is a very cheap and effective solution simply to bolt steel eye bolts through the base, to form these secure anchor points.

Large, mature trees will also need to be secured via aerial guys – typically these are galvanised wire cables looped around the tree trunks at elevation, and then led back to sturdy eye bolts welded inside the rims. A project which shows aerial guys being installed is: UNIVERSITY OF OXFORD – STUDENT ACCOMMODATION – OXFORD OX1 >>

The tree anchor eye bolts in the base of the planter [and/or the aerial guy eye bolts welded inside the rim] can also be use to assist with putting the empty planters in place, with either a forklift or telehandler.

Trees can be expensive, and they need a lot of water [particularly in the first one or two seasons]. And water must be provided throughout their life in the planter – as, unlike when planted in open ground, a tree in a planter cannot grow tap roots to access underground water.

Therefore, a tree planter specification will always need to include some kind of water supply – either an external supply fed into the planter, or a water reservoir internal to the planter. This latter option is fully discussed here: GROWING MEDIUMS AND RESERVOIRS FOR PLANTERS >>

Thermal insulation is not strictly mandatory – but the trees will thank you for it. And big trees can cost big bucks, so keeping them happy and healthy can often be cost-justified.

We use 25mm Celotex [or equivalent] insulation board, which is effective, inexpensive and lasts forever; and it also has the added benefit that it adds extra stiffness to the sides of the planter. Including labour to install, thermal insulation to all inside faces of the planter [four sides, plus the base] will cost:

L 1000 x W 1000 x H 1000mm £95

L 1200 x W 1200 x H 1100mm £130

L 1400 x W 1400 x H 1100mm £160

L 1800 x W 1800 x H 1100mm £225

L 2000 x W 2000 x H 1100mm £260

L 2400 x W 2400 x H 1100mm £325

Note: IOTA prices at February 2021

So where large specimen trees can sometimes cost thousands, thermal insulation can often be a cost-justifiable extra.

Contact IOTA T. 01934 522617